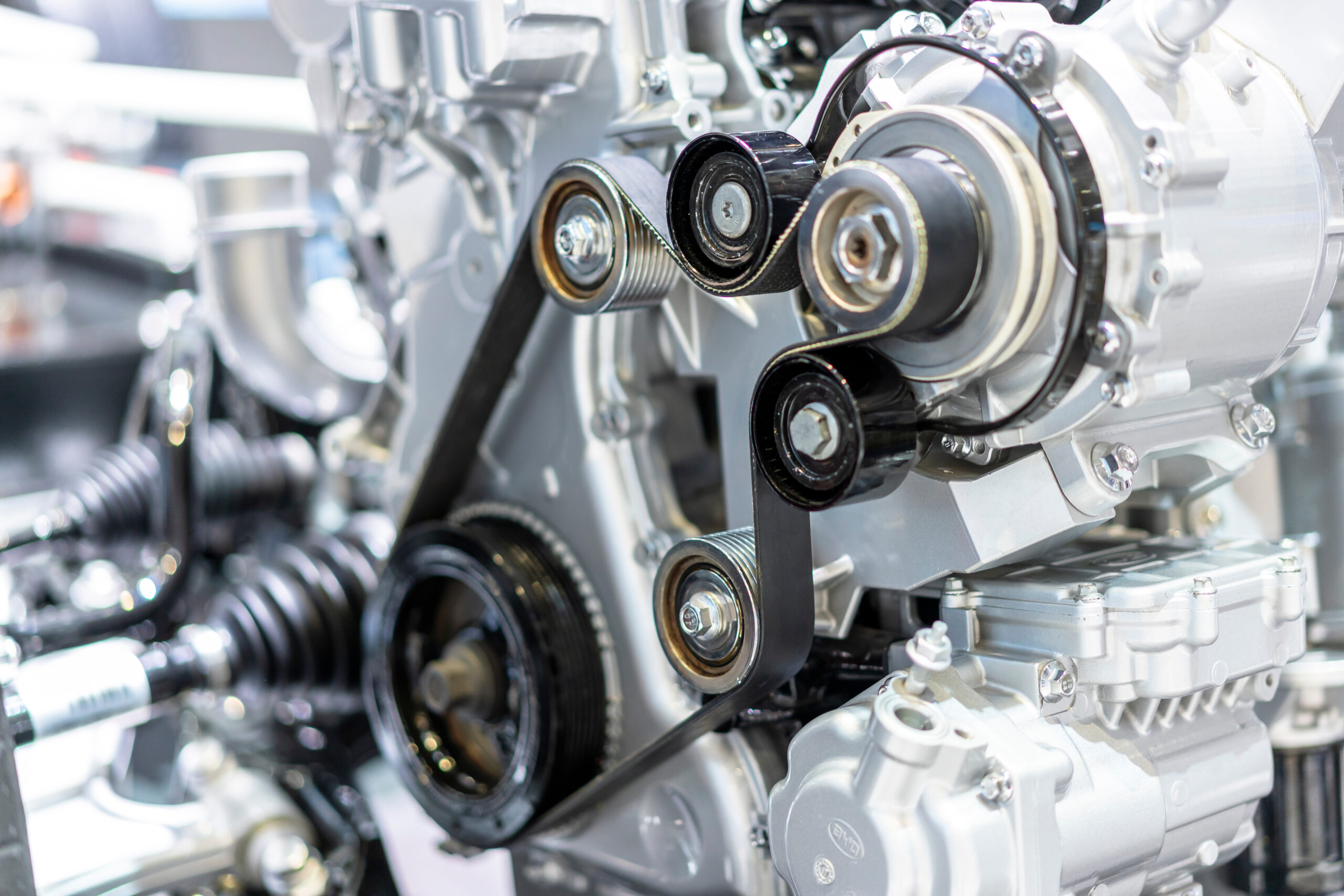

Bringing in domain expertise

We decided to bring in a team of domain experts, with specific expertise on ERP systems in Automotive companies. Domain experts can provide insights from their previous experience, and understand the dynamics, complexities and pitfalls of these assignments - and how to avoid them if possible

Requirement workshops

By early-on introducing requirement workshops with client stakeholders, we were able to identify the main goals and objectives for the project. The workshops allowed us to deepen the understanding, and brainstorm about the solution direction. By making this a collaborative session, we were able to get early alignment - of which the value must not be underestimated. This was critical to the success of the project

Applying an Agile project methodology

By introducing bi-weekly sprints, we iteratively built the product in stages - while introducing the opportunity to inspect, adapt and streamline the development process. Our client stakeholders did not only received demos, but also had the opportunity to inspect deliverables and steer our team in the right direction by providing useful insights.

Selecting suitable technology stack

As with any software development project, we thought carefully about which tech stack would work best to achieve our goal. There were three main aspects critical for the success of this project: Performance, Costs and Maintenance/longevity.

As a result, we decided to go for an Angular front-end and .NET/C# back-end, complimented with a PostgreSQL database.

We did consider MS SQL for the database, consider the fact that it integrates well with .NET. However, after reviewing the license fees for the Enterprise edition - compared to a free open-source, full featured contender in Postgres, we decided to opt for the latter without regrets.

Rigorous test approach

Ensuring the software was ready for use, bug-free and intuitive, we added a full-time QA/Tester to the team. This allowed us to get a different perspective on the software deliverables, critically reviewing what has been built.